Industry Certifications

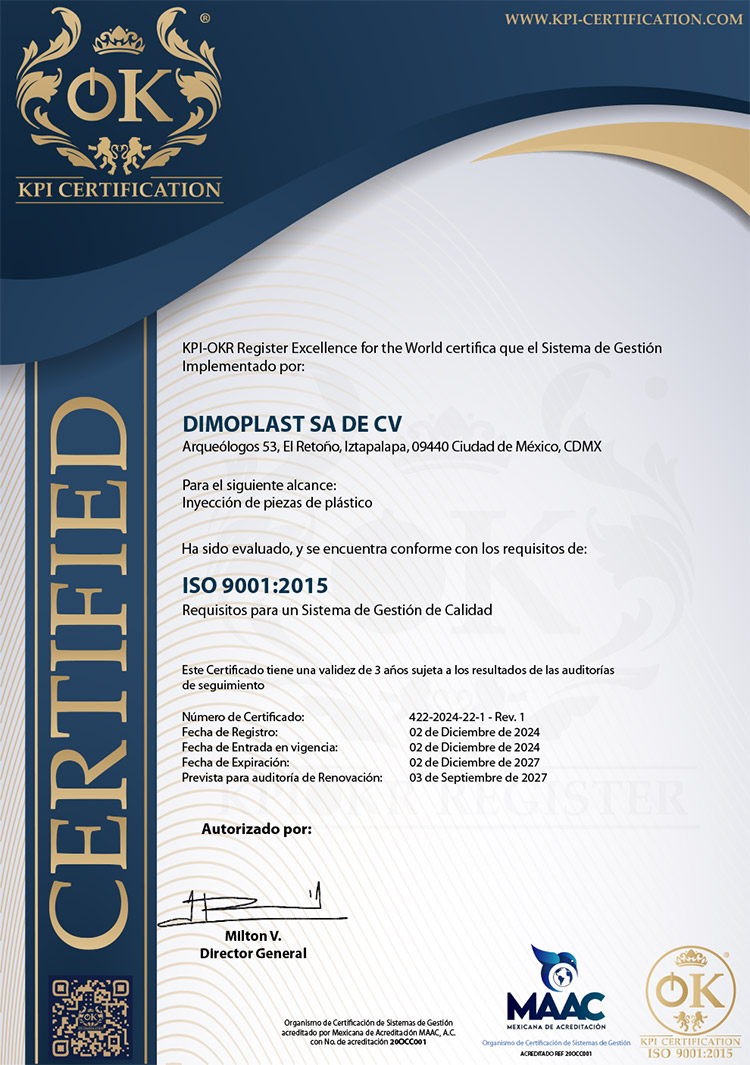

Our ambition is to be one of the best companies in the world. We constantly improve our processes to offer an optimal service; this constancy has led us to achieve our goals gradually, we managed to obtain the ISO 9001:2015 certification.

We follow high standard industry and quality certifications to ensure our customers get the highest quality plastic parts.

The aim of a plastics’ injection process is to automate parts production in a cyclic injection-molding process.

The main feature of this kind of pieces is their complex geometry which is related to particular specifications on strength, precision and finishing. These pieces, generally, are meant for the electronic and automotive industries or for specialized systems.

In Dimoplast we have the right work team and infrastructure to produce our own molds. These resources free us from depending of on third parties and helps help us with our prices and time to favor our customers.

Clients

Some of our clients.